Home >

Blower

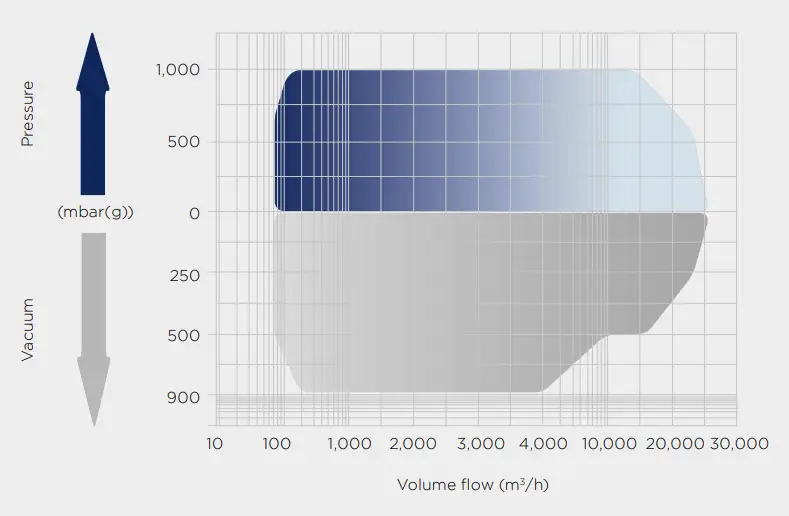

Bare Shaft 3 Lobe Blower

- Pressure to 1,000 mbar (g)

- Vacuum to 500 mbar (a)

- Air flow to 25,000 m³/h

Description

Experience high-performance with rotary tri-lobe blowers featuring a low pulse system for reduced pressure pulsations. These positive displacement units deliver 100% oil-free air, ensuring durability and a long service life. With cast iron construction and dynamically balanced impellers, they provide efficient and reliable operation.

Information

Equipped with efficient gas seals, these blowers are designed to maintain optimal performance. Their robust design and construction make them suitable for various applications, while their superior engineering minimizes maintenance requirements. Count on these rotary tri-lobe blowers for reliable and efficient air delivery in your operations.

Applications

- Waste-Water Treatement

- Cement Factories Industry

- Vacuum systems

- Lime cement fluidisation

- Combusted gas recovery

- FGD (Flue-gas Desulfurisation)

- Bed combustion fluidisation

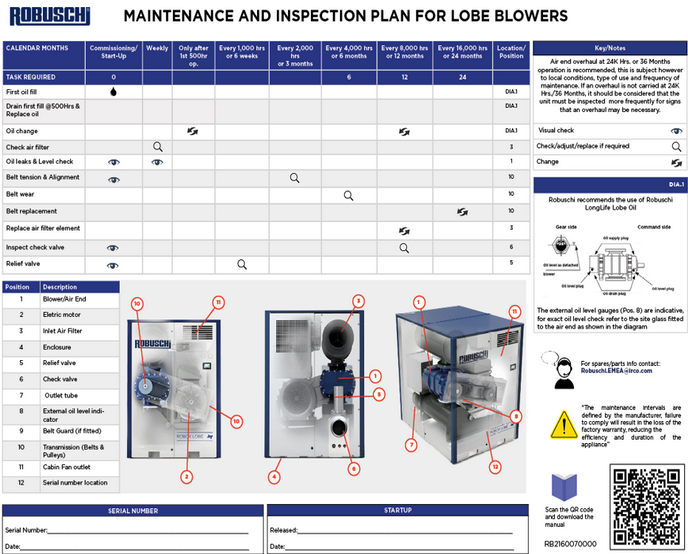

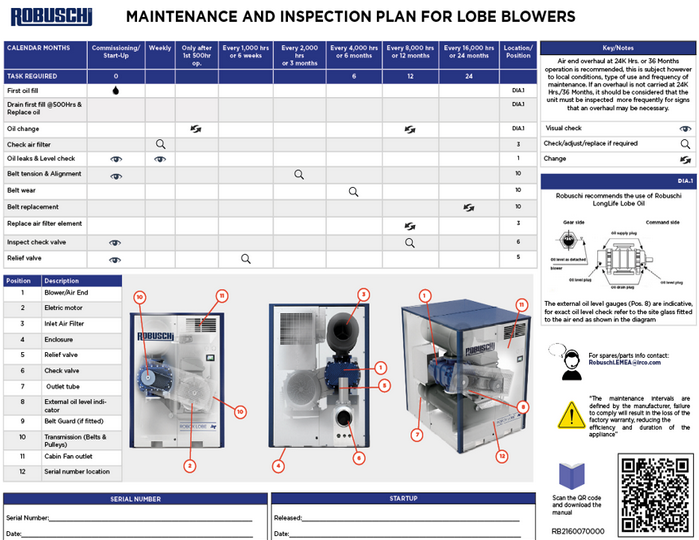

Blower Unit

- Up to 1,000 mbar(g)

- Vacuum up to 500 mbar (a)

- Maximum capacity of 10,500 m³/h

Description

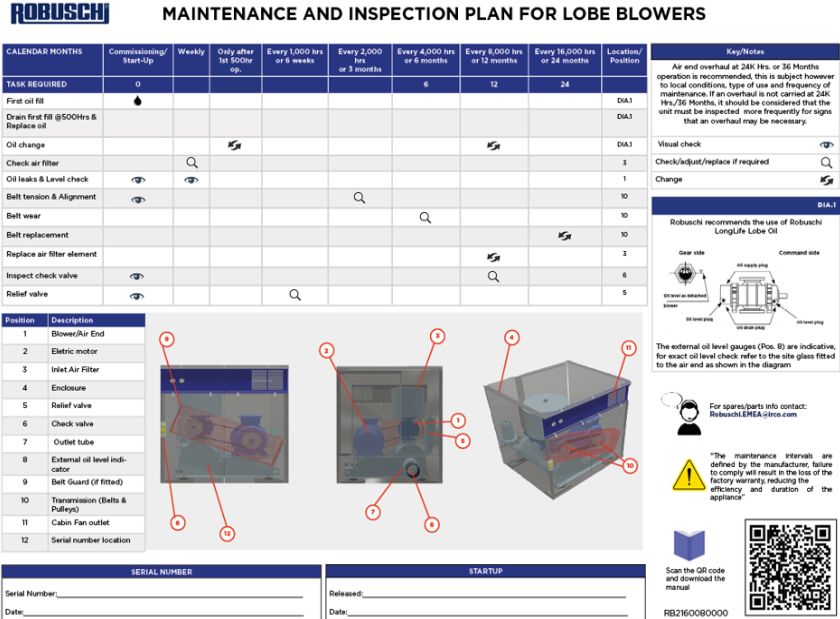

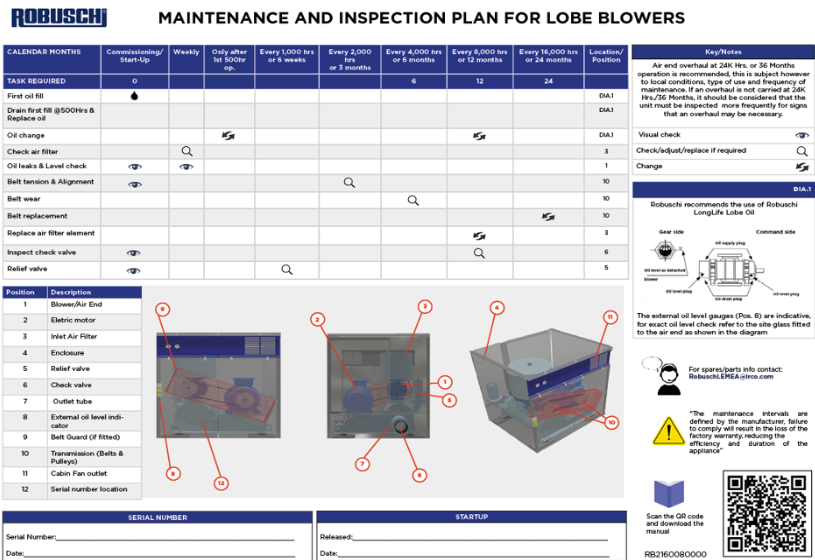

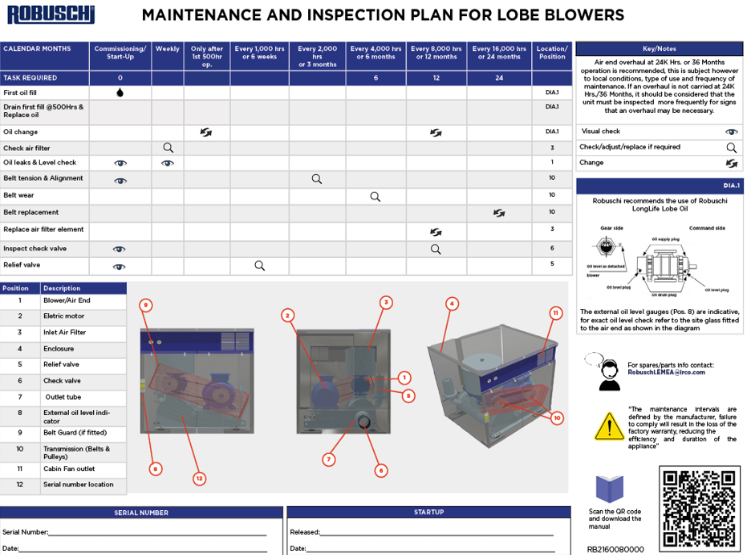

The compact blower unit offers a unique design and easy installation, optimizing floor space usage. Its exclusive features eliminate the need for ducting, making it convenient to install in various settings. Experience the benefits of a blower unit with the added advantage of screw blower technology in one package.

Information

Enjoy low noise emissions with the blower unit, thanks to its specially designed discharge and suction silencers, as well as enhanced canopy features. Installation is made easy with the flexible and user-friendly design of the blower unit. Accessible service points and removable enclosure side doors ensure convenient maintenance and upkeep.

Applications

- Wastewater Treatment.

- Aquaculture.

- Food and Beverage.

- Lime and Cement.

- Cooling and drying

- Methane gas extraction

- Feeding inert

- Blower Unit – Oil-free Premium Airend: Efficient, oil-free operation with reduced pressure pulsation.

- Synchronized gears, high-quality rotors, and durable shaft design for reliability.

- New Compact Suction and Discharge Silencers: Minimize pressure drops and reduce noise.

- Dual splash lubrication system: Requires minimal maintenance.

- State-of-the-art noise enclosure: Corrosion protection and reduced noise emissions.

- Easy electrical cable installation from top or bottom.

Bare Shaft Vacuum Blower

- Vacuum up to 100 mbar(a)

- Capacity up to 10,500 m³/h

- Vacuum of up to 93% – 28″ Hg

Description

vacuum pump series consists of 3 lobe rotary blower used as exhauster, It can reach vacuum levels of up to 93% on a dead head – 28″ Hg without the need to water inject or heat exchange.

Information

- Maximum vacuum 93% – 28”Hg on a dead head

- Gases and vapours can be handled

- Cool operating temperatures (no overheating on dead head)

- Low maintenance thanks to its robustness and heavy duty operation.

Applications

- Vacuum conveying

- Plastic granules vacuum conveying

- Food packaging, PET production

- Pick & place

- Removal of impurities

- Pulp drying

- Paper converting

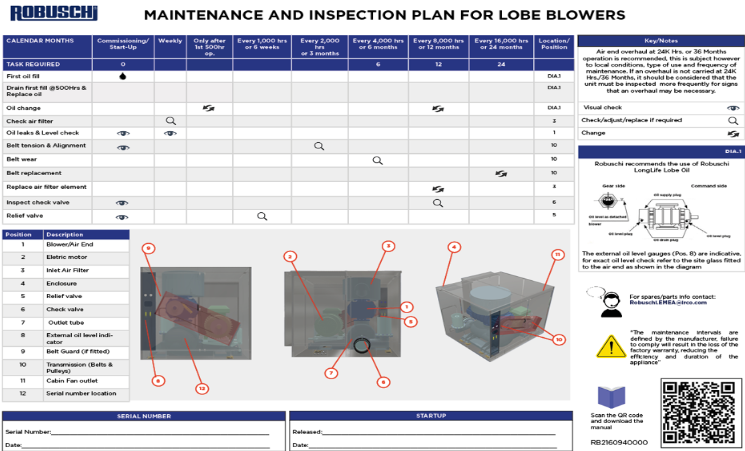

Vacuum Blower Unit

- Vacuum up to 100 mbar (a)

- Capacity up to 10,500 m³/h

- High compression ratio

Description

The vacuum blower unit, known as the vcauum blower unit – DV, offers exceptional efficiency with a maximum vacuum level of 100 mbar(a) and a flow capacity of 10,500 m3/h. Driven by an electric motor through a belt drive, this complete integrated package includes all necessary accessories and a noise enclosure for quiet operation.

Information

With the addition of a new performance cooling fan, the vacuum blower unit ensures optimal air circulation within the noise enclosure, extending its operating range capacity. It provides improved reliability and efficiency, facilitated by easy connection via a terminal board and lower enclosure temperature. The vacuum blower unit also features an optimized discharge silencer for increased energy efficiency and a robust, restyled noise enclosure suitable for heavy-duty applications in the HT version.

Applications

- Vacuum conveying

- Plastic granules vacuum conveying

- Food packaging, PET production

- Pick & place

- Removal of impurities

- Pulp drying

- Paper converting

- Cooling fan: Improves air circulation, extends operating range capacity, enhances reliability, allows easy connection via terminal board, and improves efficiency due to lower inner enclosure temperature.

- Discharge silencer optimization: New design increases energy efficiency.

- Enhanced noise enclosure: robust for heavy-duty applications (HT version).

Applications