Home >

Pump

Multistage Pump

- Maximum flow rate: 45 m3/h

- Maximum head: 300 mwc

- Maximum pressure: 30 BAR

- Maximum temperature: 140° C

Description

Multistage pumps are efficient and reliable pumps with multiple impellers arranged in series, generating high pressures. They find applications in industries like oil and gas, power generation, and water treatment.

Information

Multistage pumps offer compact designs and high-pressure capabilities, making them ideal for water supply, boiler feed, reverse osmosis, and other demanding processes in various industries.

Applications

- boiler feeding

- fire-fighting

- autoclave

- water supply

- washing plant and irrigation

- applications to pump hydrocarbons.

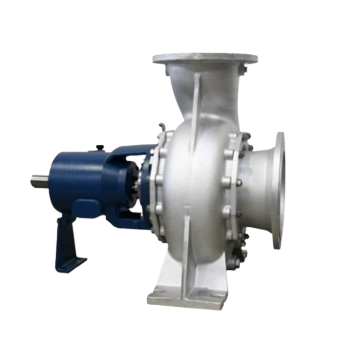

Centrfigual SR

- Maximum flow rate: 500 m3/h

- Maximum head: 140 mwc

- Maximum pressure: 16 BAR

- Maximum temperature: 220° C

Description

Centrifugal pumps are widely used for fluid transportation, converting rotational energy into kinetic energy. They are known for simplicity, high flow rates, and versatility in industries like water supply and chemical processing.

Information

Centrifugal pumps generate high flow rates with low head pressures. They consist of an impeller spinning in a casing, propelling fluid outward. They offer efficiency, reliability, and easy maintenance, making them popular in various industries.

Applications

- harsh applications

- suspended solids

- high temperatures & viscosities

Centrfigual RB

- Capacity up to 2,600 m³/h

- Head up to 140 m

- Avilable with closed impellers

Description

Centrifugal pumps are widely used for fluid transportation, converting rotational energy into kinetic energy. They are known for simplicity, high flow rates, and versatility in industries like water supply and chemical processing.

Information

Centrifugal pumps generate high flow rates with low head pressures. They consist of an impeller spinning in a casing, propelling fluid outward. They offer efficiency, reliability, and easy maintenance, making them popular in various industries.

Applications

- water supply

- industrial applications

- acooling water circulation

- fire-fighting plants.

Gear Pump

- Flow rate: max. 3.400 cm³ / rev

- Maxim pressure: max. 25 bar

- Operating temp: max. 250 °C

- Viscosity : max. 100.000 mm² / s

Description

Gear pumps are commonly employed for fluid transfer in various industries. They utilize interlocking gears to generate flow and are known for their compact design and reliable performance. Gear pumps are often used for applications involving paints, varnishes, lubricating oils, and other media.

Information

Gear pumps operate by the meshing action of interlocking gears, creating a positive displacement to move the fluid. They offer precise and consistent flow rates, making them suitable for applications that require accurate metering or dosing. Gear pumps are favored for their durability, ease of maintenance, and versatility across different industries.

Applications

pumping high viscosity fluids such as

- oil, paints,

- resins

- foodstuffs

- bitumen,

- fats

- syrups

- chocolate

Applications