Home >

Compressor

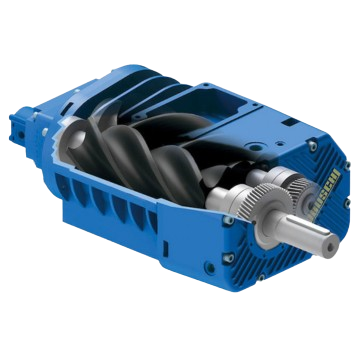

Bare Shaft Screw Compressor

- Low pressure up to 2,500 mbar(g)

- High level of efficiency (> 75%)

- Capacity up to 10,100 m³/h

Description

The screw compressor unit, also referred to as an oil-free low pressure screw compressor airend or “helical screw” compressor, operates through rotary motion. It delivers a constant flow and variable pressure, independent of speed, thanks to its helical profile rotors housed within a casing.

Information

These rotors, one male with 3 convex lobes and one female with 5 concave lobes, rotate in opposite directions, creating working chambers that compress air as it moves from the intake to the compression side. The screw compressor unit offers advantages such as steady, non-pulsating airflow, minimal maintenance, and extended lifespan due to precise tolerances and an oil-free design.

Applications

- Application

- Application

- Application

- Application

- Application

Screw Compressor Unit

- Pressure up to 1,000 mbar(g)

- Vacuum up to 300 mbar(a)

- Maximum capacity of 10,100 m³/h

Description

The screw compressor unit, also referred to as an oil-free low pressure screw compressor airend or “helical screw” compressor, operates through rotary motion. It delivers a constant flow and variable pressure, independent of speed, thanks to its helical profile rotors housed within a casing.

Information

These rotors, one male with 3 convex lobes and one female with 5 concave lobes, rotate in opposite directions, creating working chambers that compress air as it moves from the intake to the compression side. The screw compressor unit offers advantages such as steady, non-pulsating airflow, minimal maintenance, and extended lifespan due to precise tolerances and an oil-free design.

Applications

- Application

- Application

- Application

- Application

- Application

- Screw blower unit with CDL airend integration.

- Silencer with dedicated filter cartridge for enhanced reliability and easier maintenance.

- Advanced lubrication systems.

- State-of-the-art noise enclosure.

Applications